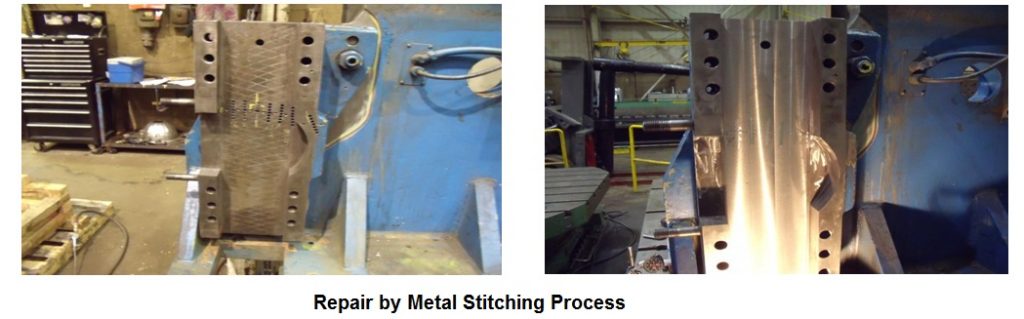

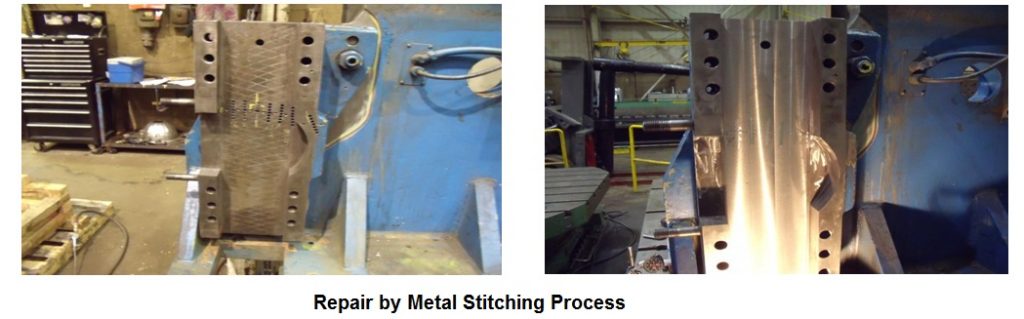

There are many advantages of using onsite metal locking and metal stitching processes to repair cracks and broken casting.

Some are listed below:

- Metal locking, metal stitching, and metal surgery is a cold repair process. No heat is generated.

- Onsite metal locking and metal stitching is a cost-effective repair process, as there is no need to disassemble the equipment and transport it to the repair workshop. We have portable pneumatic tools that can easily be carried to the site.

- We use high-quality metal keys, locks, and other consumables used in this process to ensure the proper repair of the damaged casting.

- Metal locking and metal stitching process ensures the proper crack repair, recreating higher original strength.

- All components manufactured of cast iron and aluminium can be repaired by metal locking and metal stitching process with guarantee.

In case of any emergency or breakdown, please email us at info@rapowersolutions.com. We can depute our technicians with all the necessary portable equipment for repair.

Metal Stitching & Metal Locking is absolute for repairing the following:

- Cracked engine block

- Heavy-duty industrial machinery

- Turbocharger

- Engine bedplate

- Cylinder Liners, Pistons, Pump casings, gearboxes